Disconnected systems hinder decision-making. Without tight integration between WMS and systems like ERP, MES, and TMS, manufacturers face data silos and delays, leading to poor coordination across production, warehousing, and shipping.

Lack of visibility causes planning failures. When inventory data isn’t current or accurate, it leads to stockouts, overproduction, or delayed fulfillment – disrupting manufacturing flow and customer commitments.

Managing multiple sites is operationally inconsistent. With varying workflows, compliance rules, and visibility levels, global manufacturers face high IT complexity, data fragmentation, and inefficiencies across sites.

Our Advice

Critical Insight

CIOs must be deliberate in defining the organizational needs that drive their WMS transformation. Attempting to prioritize modernization for the sake of modernization will dilute impact, yet doing nothing under the guise of cost containment will leave you vulnerable. CIOs must build a roadmap that accounts for clear trade-offs and focused sequencing in line with what the business wants to achieve and overall resilience.

Impact and Result

A detailed methodology to prioritize business requirements for WMS solution selection.

Future-Proof Your Warehouse Operations With Modern Warehouse Management Systems

Use technology to unlock the potential of your warehouses.

Analyst perspective

Use technology to unlock the potential of your warehouses.

The warehouse has always been a critical part of the manufacturing enterprise. Warehouse management systems (WMS) are a critical enabler of visibility, responsiveness, and cost control. Yet many manufacturers still operate with fragmented processes, outdated systems, and limited data, leaving their warehouses vulnerable to disruption and inefficiency.

This research aims to equip CIOs with the insights they need to modernize and elevate their warehouses. It explores the core challenges manufacturers are facing in their warehouses, reflecting the underlying architectural, governance, and integration gaps that CIOs are uniquely positioned to address. This is no longer simply about automating tasks; it is about embedding the warehouse into the digital supply chain.

CIOs must ensure that WMS platforms support integration with manufacturing systems such as enterprise resource planning (ERP), manufacturing execution systems (MES), and transportation management systems (TMS), enable data-driven decision-making, and scale globally while adapting to local compliance and operational needs. Cloud deployments, edge computing, and low-code configurability are emerging as key enablers of the modern warehouse.

When implemented, the right WMS can help organizations adapt to volatility, policy changes, and sourcing strategies; accelerate order fulfillment; and respond proactively to disruptions. This blueprint provides a framework for evaluating WMS capabilities, offers guidance on overcoming barriers, and highlights the strategic decisions CIOs must make to future-proof their warehouse operations. By leading with technology, CIOs can turn the warehouse into a dynamic, intelligent node in the broader manufacturing ecosystem.

Shreyas Shukla

Research Director, Industry

Info-Tech Research Group

Executive summary

Your Challenge

Disconnected systems hinder decision-making. Without tight integration between WMS and systems like ERP, MES, and TMS, manufacturers face data silos and delays, leading to poor coordination across production, warehousing, and shipping.

Lack of visibility causes planning failures. When inventory data isn't current or accurate, it leads to stockouts, overproduction, or delayed fulfillment, disrupting manufacturing flow and customer commitments.

Managing multiple sites is operationally inconsistent. With varying workflows, compliance rules, and visibility levels, global manufacturers face high IT complexity, data fragmentation, and inefficiencies across sites.

Common Obstacles

Manufacturers rely on legacy WMS platforms that lack integration capabilities. Integration efforts are frequently delayed by misaligned upgrade roadmaps, and poor data standardization undermines even the most technically connected environments.

Visibility is limited by outdated data-capture methods, such as batch updates or manual entries, and by the slow adoption of modern technologies like internet of things (IoT), radio frequency identification (RFID), and barcode scanning.

Local compliance needs and customization demands create divergence across sites, while IT teams struggle to implement standardized architecture due to limited resources and pushback from local teams.

Info-Tech's Approach

Manufacturers should implement an integration platform or middleware that connects a WMS to critical systems using APIs and a shared data model, ensuring real-time data flow, minimizing manual reentry, and enabling more accurate decision-making.

Invest in data capture and inventory intelligence technologies and enable real-time inventory visibility tools with predictive analytics to manage stock levels, reduce shortages, and improve production planning.

Establish global process templates with localized flexibility. Pair this with centralized governance, modern WMS platforms, and strong change management to align operations while respecting regional requirements.

CIOs can directly influence supply chain resilience by championing a modern WMS. However, it is also crucial to champion the right approach to selecting a WMS, addressing business needs, improvement actions, and organizational objectives.

Warehousing is entering an era of tight capacity, persistent cost pressures, and structural imbalances

Warehousing for manufacturers is entering a cost-intensive, capacity-constrained, and bifurcated era. Small firms are more vulnerable, while large players will benefit from their ability to absorb and maneuver. Warehousing investments will pivot from expansion to efficiency. The most resilient manufacturers will be those that balance real-time responsiveness, cross-tier collaboration, and data-driven optimization rather than simply expanding physical space.

|

Growing |

Slowing |

No Change |

|

Inventory Costs |

Inventory Levels |

Warehousing Capacity |

|

Warehousing Utilization |

Warehouse Prices |

|

|

Transportation Prices |

Transport Capacity |

|

|

Transport Utilization |

Short-Term Outlook

Short-Term Outlook |

|---|

|

Long-Term Outlook |

|

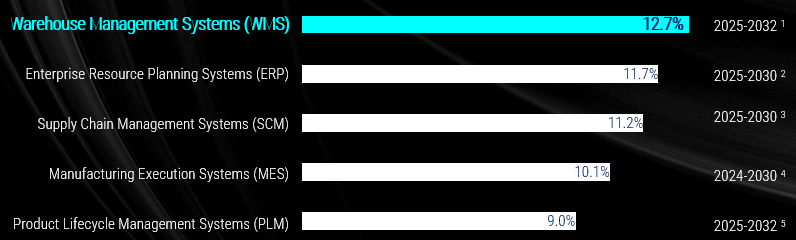

Projected CAGR for WMS platforms are the highest among manufacturing-specific software solutions

This growth outlook underscores the rising strategic importance of warehouse operations, supply chain orchestration, and real-time execution platforms in modern manufacturing architectures.

Projected CAGR across major enterprise platforms

- WMS leads in mid‑double‑digit growth (~12%‑13%) due to increasing investments in warehouse automation, omnichannel logistics, and system integration.

- ERP and SCM share similar growth rates (~11%-12%), reflecting steady demand for end-to-end supply chain and enterprise resource planning modernization.

- MES is slated for moderate growth (~10%), driven by Industry 4.0 adoption and real-time production execution needs.

- PLM grows slightly slower (~9%), reflecting its niche positioning in product design, development, and collaboration operations.

Sources:

- Fortune Business Insights, 2025

- "ERP Software Market," Grand View Research, 2025

- "Supply Chain Management Market Report," Grand View Research, 2025

- MarketsandMarkets, 2025

- InsightGrid Marketing via LinkedIn, 2025

Your challenge

Disconnected systems hinder decision-making.

Many manufacturers still operate with siloed warehouse systems that lack seamless integration with enterprise platforms like ERP, MES, TMS, and demand planning tools. This disconnection results in fragmented data, delayed updates, and inconsistent process execution across departments. These inefficiencies compound daily and prevent leaders from making timely, informed decisions that align supply with demand. Ultimately, disconnected systems create a brittle operational backbone, unable to respond swiftly to disruptions or opportunities.

Lack of visibility causes planning failures.

Inventory visibility is foundational to effective warehouse planning, but many manufacturers continue to rely on manual processes. The absence of data leaves planners operating on assumptions rather than facts. When planners cannot see what is on hand, where it is, or what is in motion, they tie up capital in excess inventory or cause stockouts and production stoppages. Visibility gaps also impact order accuracy, cycle times, and service levels.

Managing multiple sites is operationally inconsistent.

As manufacturers expand their operational footprint, maintaining consistent processes and controls across sites becomes increasingly difficult. Each warehouse may use different WMS platforms, configurations, workflows, and sometimes even different levels of automation and data maturity. This leads to inefficiencies in cross-site planning, performance monitoring, compliance enforcement, and resource allocation. It becomes challenging to balance centralized governance with localized flexibility, especially in environments with varied regulatory requirements, labor structures, and customer expectations.

Visibility gaps in the warehouse erode agility, inflate costs, and leave manufacturers exposed to disruption. WMS modernization is critical to resilience.

Top challenges that organizations face in relation to warehouse operations

|

Issues |

Ranking (Highest to Lowest %) |

||

|---|---|---|---|

|

2024 |

2023 |

2022 |

|

|

Outdated storage, picking, or material handling equipment |

1 |

3 |

4 |

|

Supply chain disruptions |

2 |

4 |

1 |

|

Insufficient space and/or required modifications to operations |

3 |

1 |

2 |

|

Inability to attract and retain a qualified hourly workforce |

4 |

2 |

3 |

|

Inability to attract and retain qualified supervision |

5 |

6 |

7 |

|

Obsolete layout for current requirements |

6 |

5 |

5 |

|

Lack of SKU information in system |

7 |

7 |

8 |

|

Inadequate information systems support |

8 |

5 |

7 |

|

Lack of higher management support |

8 |

6 |

6 |

WMS penetration is increasing.

93% of respondents use some type of WMS software.

Warehouse equipment is still seeing underinvestment.

45% of respondents cite outdated storage, picking, or material handling equipment as a major issue.

Common obstacles

Manufacturers rely on legacy WMS platforms that lack integration capabilities.

Manufacturers are constrained by legacy WMS platforms. These legacy systems often use proprietary data formats, lack modern APIs, and require extensive custom coding to connect with ERP, MES, or transportation systems. The result is a complex and costly integration architecture that limits the CIO's ability to implement digital transformation initiatives and slows down responsiveness to changes in production, customer demand, or logistics constraints.

Visibility is limited by outdated data capture methods and the slow adoption of modern technologies.

Many warehouses still rely on manual entry, periodic scanning, and batch-based updates to track inventory movements, leading to delays, errors, and data inconsistencies. The adoption of technologies such as RFID, IoT sensors, edge devices, and mobile workflows remains slow. As a result, key decisions are made based on stale or incomplete information, undermining forecasting, replenishment, and fulfillment strategies. Without investing in modern data capture infrastructure, manufacturers cannot achieve the visibility needed for adaptive operations.

Local compliance needs and customization demands create divergence across sites.

In multisite manufacturing environments, regional regulations and customer requirements often necessitate some degree of localization in warehouse processes. However, without a clear governance framework and standardized global templates, this flexibility leads to configuration drift, resulting in inconsistent data structures, fragmented reporting, and varying levels of system maturity. CIOs find it challenging to enforce enterprise standards or gain a unified view of operations. This scenario also increases IT overhead and creates barriers to scaling best practices across the network.

Manufacturers must constantly deal with deep-rooted fragmentation that undermines agility, scalability, and resilience. CIOs must overcome these obstacles with a centrally governed WMS architecture.

Existing systems limit manufacturers' ability to respond to rapid shifts in operating conditions

|

Legacy WMS Platforms Limit Integration and Responsiveness

|

Outdated Data Capture Methods Undermine Visibility and Decision-Making

|

Fragmented Site Configurations Obstruct Standardization and Scale

|

|

Indicators in the May 2025 LMI Report |

||

|---|---|---|

|

|

|

Source: Logistics Managers' Index, 2025

Info-Tech's approach

Implement an integration platform or middleware that connects a WMS with critical systems.

Overcoming system fragmentation is crucial for manufacturers. An integration platform or middleware will ensure consistent information across systems, enabling more accurate, timely decision-making. It also allows IT teams to decouple point-to-point integrations, accelerate digital initiatives, and future-proof the architecture for new technologies such as IoT or advanced analytics.

Invest in data-capture and inventory-intelligence technologies.

CIOs should prioritize deploying real-time data-capture technologies such as barcode/RFID scanning, IoT sensors, and edge computing to automate the collection of inventory movements, equipment status, and environmental conditions. Using this data with AI-powered inventory analytics enables dynamic cycle counting, predictive replenishment, and accurate inventory forecasting. These investments reduce dependency on manual processes, improve inventory accuracy, and unlock the visibility needed to support agile manufacturing and fulfillment strategies.

Establish global process templates with localized flexibility.

Manufacturers should standardize core WMS processes through globally governed templates, while allowing configurable elements to meet regional compliance or operational needs. This ensures consistent data structures and performance baselines. Centralized governance combined with a flexible configuration layer also simplifies training, accelerates onboarding, and reduces long-term system maintenance costs.

A modern warehouse isn't just about software upgrades. CIOs must build an integrated, intelligent, and standardized WMS ecosystem.

Choosing the right WMS results in cost savings, customer satisfaction, and a competitive edge in the marketplace

A WMS decision goes beyond just software selection; it reflects your organization's strategic priorities, scalability needs, and operational discipline. By aligning WMS capabilities with sector-specific demands and business objectives, companies can unlock long-term value across fulfillment, labor, and network-wide performance.

|

Improved Accuracy |

Higher Speed |

Reduced Operational Costs |

Enhanced Visibility |

Greater Flexibility |

|

Better Productivity |

Improved Compliance |

Advanced Capabilities |

Higher Customer Satisfaction |

Data-Driven Decision-Making |

Future-Proof Your Warehouse Operations With Modern Warehouse Management Systems Use technology to unlock the potential of your warehouses.

Modern warehouse management systems are very capable. But don't jump straight to solutions.

Be deliberate in defining the organizational needs that drive your WMS transformation.

- Understand your goals.

- Assess your maturity.

- Identify capabilities to replace, reconfigure, retool, or retain.

- Identify improvement actions.

- Build a roadmap and a custom vendor evaluation list.

Perform focused sequencing of initiatives in line with what the business wants to achieve.

Retain what works.

Replace, reconfigure, retool what doesn't.

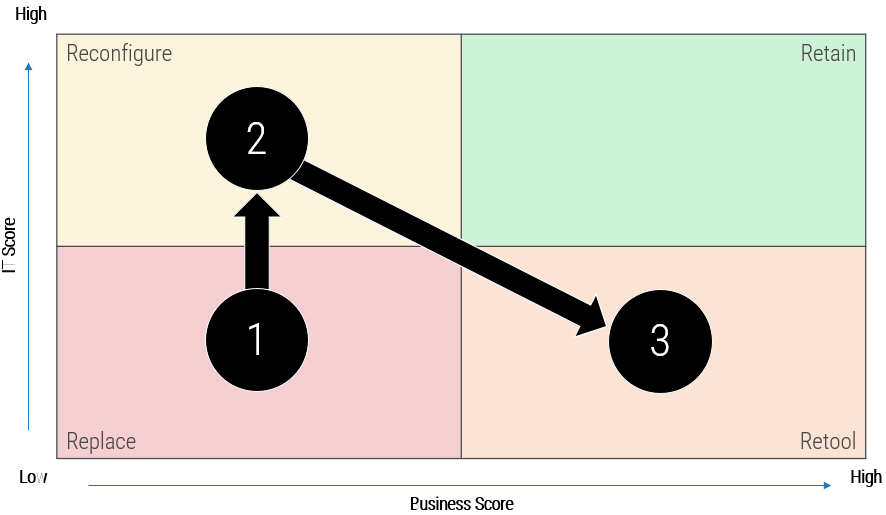

Use Info-Tech's 4R WMS capability quadrant to retool, reconfigure, replace, or retain each capability intelligently

|

Replace: |

|---|---|

|

Reconfigure: |

|

|

Retool: |

|

|

Retain: |

Info-Tech's methodology for future-proofing manufacturing warehouse technologies

|

1. Establish Your Current State |

2. Assess Capability Maturity and Satisfaction |

3. Analyze Gaps and Prioritize Needs |

4. Define Actions and Opportunities |

5. Design Modernization Roadmap |

|

|---|---|---|---|---|---|

|

Phase Steps |

|

|

|

|

|

|

Phase Outcomes |

Obtain a comprehensive understanding of the organization's existing warehouse management landscape, including architecture, processes, and performance. Clarify what systems are in place, how processes are executed today, and what integration, data, and organizational challenges may exist. |

Evaluate each Level 2 warehouse capability to determine how mature and effective it is in the current state and how satisfied users and support staff are with it. Highlight strengths, weaknesses, and misalignments between what the business needs and what technology delivers. |

Identify where the largest capability and performance gaps exist and understand their urgency and impact. Heat maps and quadrant views are used to group capabilities into categories, enabling leaders to focus on areas that need the most immediate attention and offer the greatest return. |

Outline specific improvement actions that IT and business teams can take to improve supporting technology, integration, automation or workflows. Assess the relative effort and complexity associated with these actions and think through feasibility and sequencing. |

Produce a sequenced, actionable roadmap that aligns improvement efforts with organizational goals, available resources, and realistic timelines. Establish custom, prioritized criteria to compare available vendor options in the marketplace. |

Before you proceed

This research is designed to guide CIOs through actionable strategies to transform warehouse management capabilities, integrate fragmented systems, and future-proof warehouse operations.

Before acting on the recommendations outlined, readers should take time to thoughtfully prepare the organization, ensuring that the right participants, structures, and expectations are in place to support a successful warehouse transformation.

To get full value from this research and its accompanying assessment and prioritization tool, organizations should be prepared with:

- The proper representation from Supply Chain, Operations, IT, Finance, and Quality to ensure that modernization efforts address full lifecycle warehouse management needs.

- Participation from frontline warehouse managers, planners, system owners, quality control leads, and IT support teams.

- An inventory of all warehouse-related systems and integration points, along with a clear understanding of the structure and governance of key data (e.g. inventory, locations, SKU attributes).

This research is designed for manufacturers of all sizes and across all sectors, from discrete to process industries. Whether operating regionally or globally, the insights and tools provided are intended to support organizations at any stage of their WMS modernization journey.

Consider these resources alongside this project

If you are new to the world of WMS:

- Observe warehouse workflows firsthand. Direct exposure to inbound, storage, picking, and outbound processes will help you quickly identify system inefficiencies, bottlenecks, and user pain points more effectively than any report.

- Speak with warehouse users at all levels. Don't rely solely on insights from IT or operations leads. Schedule short, focused conversations with warehouse supervisors, forklift operators, inventory controllers, and shift leads. Their lived experiences will sharpen your understanding of where modernization can have the biggest impact.

- Build a simple warehouse system inventory sheet. List all WMS and related systems (e.g. ERP, WES, WCS, label printing), their owners, core functions, known limitations, and integration touchpoints. This overview is critical to identify overlaps, gaps, and data silos early in the journey.

While this research explores warehouse management capabilities and architecture in depth, these preparatory steps will help you lay the foundation for meaningful improvements in your warehouse operations.

If you are looking to establish real-time integrated supply chain views for quick decision-making, see Info-Tech's Harmonizing Complexity: Control Tower Integrationblueprint.

If you are looking to compare the capabilities of real-world warehouse management solutions, see SoftwareReviews' Warehouse Management Systems category.

Blueprint deliverables

Each step of this blueprint is accompanied by supporting deliverables to help you accomplish your goals.

Key deliverables:

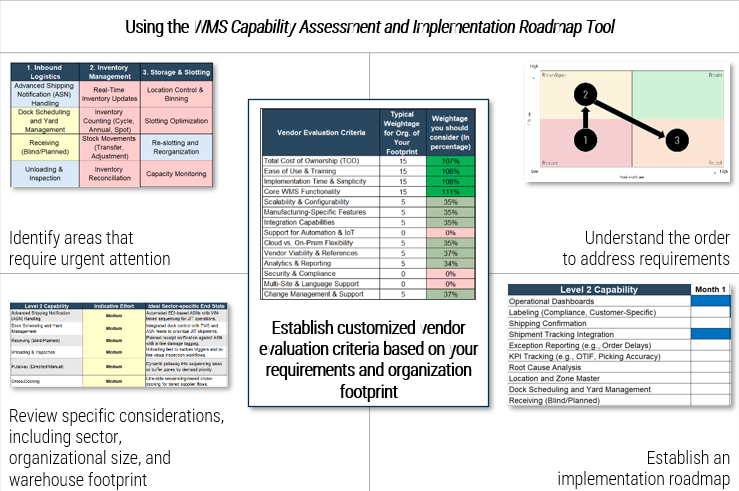

WMS Capability Assessment and Implementation Roadmap Tool

This tool is designed to help you:

- Assess your current capability maturity across key Level 1 and Level 2 WMS functions.

- Define your desired end state based on sector-specific needs, footprint, and business goals.

- Receive tailored recommendations and improvement priorities aligned to your transformation objectives.

The tool provides a guided, repeatable framework to align WMS transformation with business strategy, operational realities, IT satisfaction, and digital readiness, ultimately supporting a more agile, intelligent, and resilient warehouse management ecosystem.

Blueprint benefits

|

IT Benefits |

Business Benefits |

|---|---|

|

|

Insight summary

CIOs can directly influence supply chain resilience by championing a unified, scalable, seamlessly integrated, and intelligently automated WMS architecture.

A modern warehouse management technology landscape not only enhances fulfillment agility and accuracy but also equips the organization with real-time operational intelligence, crucial for navigating supply chain disruptions, labor volatility, and increasing customer expectations.

CIOs must be deliberate in defining the organizational needs that drive their WMS transformation.

Attempting to prioritize modernization for its own sake will dilute impact, while doing nothing under the guise of cost containment will leave you vulnerable.

There is an effective middle path in the form of a roadmap that accounts for clear trade-offs and focused sequencing, aligned with what the business wants to achieve and overall resilience.

|

1 |

2 |

3 |

4 |

5 |

|

Establish Your Current State |

Assess Capability Maturity and Satisfaction |

Analyze Gaps and Prioritize Needs |

Define Actions and Opportunities |

Design Roadmap |

|

CIOs must gain the visibility needed to rationalize technical debt and prepare WMS ecosystem for modernization. |

CIOs must engage both business and IT stakeholders to advocate for the right improvements to serve broader organizational goals. |

CIOs need to prioritize technical interventions by business value and implementation feasibility and shift conversations from reactive complaints to actionable gaps. |

CIOs must distinguish between quick fixes and foundational redesigns, ensuring IT actions align to the right themes for the organization. |

CIOs must champion a sequenced, cross-functional implementation plan that reflects business urgency, technical complexity, and site-specific readiness. |

Measure the value of this blueprint

How can you measure the value of following Info-Tech's approach?

The average IT consulting rate in the United States is $100 to $250 per hour (MOR, 2025).

The cost and effort involved in undertaking a warehouse management system transformation exercise varies depending on the size and scope of the project. The average price of a well-designed and executed WMS transformation exercise ranges from US$33,000 to US$44,000 at the lower end (assuming a two-member team charging the hourly average of US$100).

With Info-Tech Resources | Without Info-Tech Resources | |||

Project Steps | Time | Average Cost (USD) | Time | |

Establish Your Current State | 1 day | $6,000-$8,000 | 1 week | |

Assess Capability Maturity and Satisfaction | 1-1.5 days | $12,000-$16,000 | 2 weeks | |

Analyze Gaps and Prioritize Needs | 1 day | $3,000-$4,000 | 0.5 week | |

Define Actions and Opportunities | 1.5 days | $6,000-$8,000 | 1 week | |

Design Modernization Roadmap | 1-1.5 days | $6,000-$8,000 | 1 week | |

Effort | < than 7 business days | $33,000-$44,000 | 5-6 weeks | |

This blueprint will accelerate your warehouse management system transformation exercise.

We include all the guidance, tools, and templates you need to implement this program successfully.

Reach out to advisory services for assistance as you work through the blueprint or request a workshop engagement and let us do the heavy lifting.